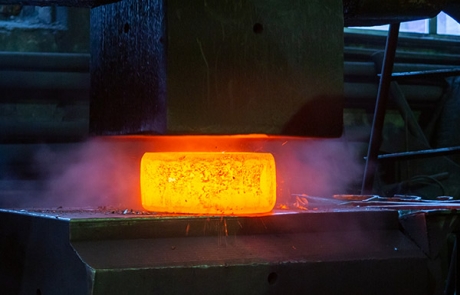

PRODUCTION PROCESS

HOT FORGING AND CASTING

This activity allows MFB to obtain the raw material products for the machining phase. The development of all the tools needed during this phase is carried out by our R&D Department. This includes forging molds, casting tools, molding plugs and so on.

According to the different shape of the product, MFB can produce:

- Hot forged blanks

- Cast blanks

- Die cast blanks

- Gravity cast blanks

One of the most important plus points for MFB is the possibility to carry out transition analysis in order to switch cast products into hot forged products or viceversa if needed.

FROM DESIGN TO PRODUCTION

MFB method is the main feature which differentiates us from the competition:

We offer to customers the FREE SERVICE of our R&D Department, specialized in the optimization of the metal components (both new projects or existing products)

The aim is reducing machining times and weight of the components to lower costs without changing product’s characteristics

Many times a co-engineering activity is required

If the optimization is reached, we obtain two results → savings for our clients and new items to be produced by MFB