QUALITY AND SUSTAINABILITY”

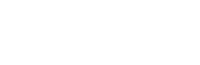

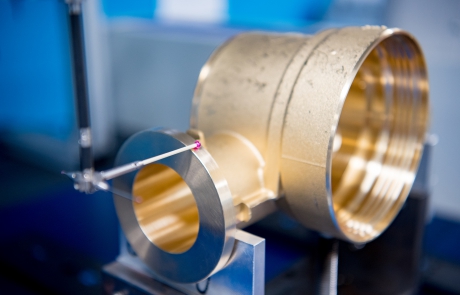

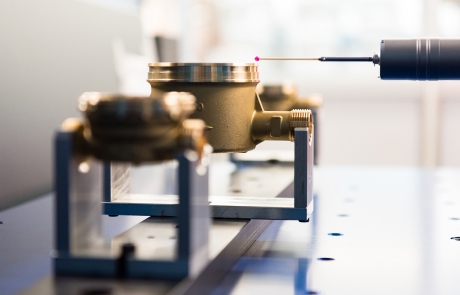

METROLOGY LAB

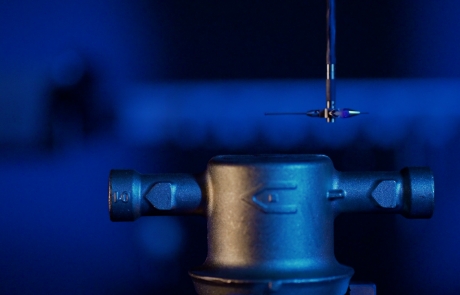

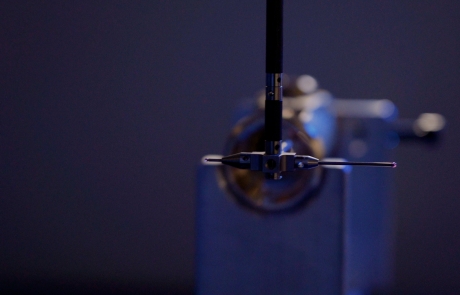

MFB relies on a metrology laboratory equipped with two Zeiss three-dimensional machines with laser scanning sensors which allow optimal measurement of any feature.

There are also several other instruments and softwares including profile projectors, roughness testers, in-line measuring tools, SPC system and so on.

All measuring and monitoring equipment is regularly calibrated by accredited laboratories.

FROM DESIGN TO PRODUCTION

MFB method is the main feature which differentiates us from the competition:

We offer to customers the FREE SERVICE of our R&D Department, specialized in the optimization of the metal components (both new projects or existing products)

The aim is reducing machining times and weight of the components to lower costs without changing product’s characteristics

Many times a co-engineering activity is required

If the optimization is reached, we obtain two results → savings for our clients and new items to be produced by MFB